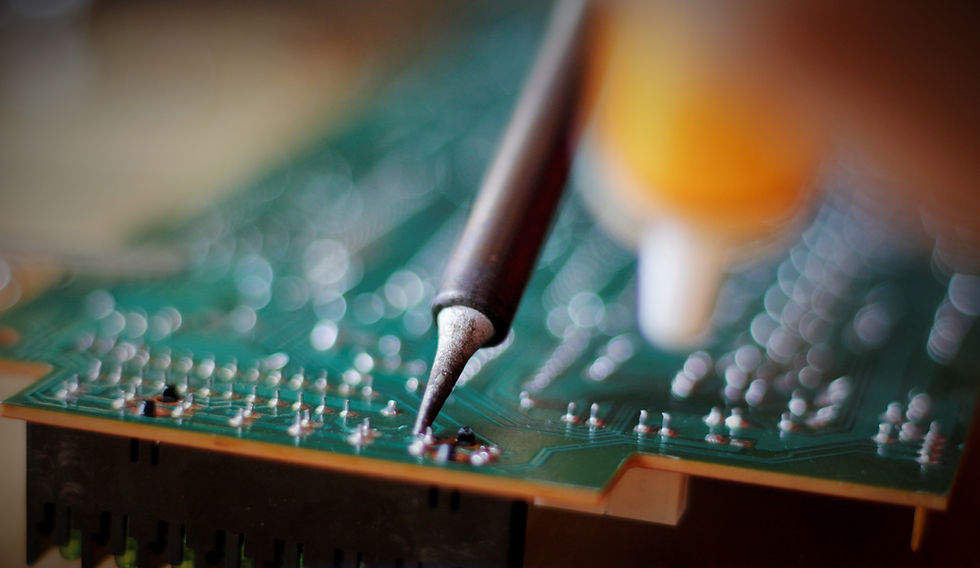

Common mistakes to avoid when designing your printed circuit board

- mike9983

- Sep 16, 2022

- 3 min read

Updated: Dec 8, 2022

As a manufacturer of printed circuit boards (PCBs), we have seen a wide range of PCB designs, both good and bad. In this blog post, we'll share some common mistakes that we see in PCB design, and how you can avoid them to ensure that your PCBs are of the highest quality.

Not considering the end-use environment

One common mistake is to design a PCB without considering the environment in which it will be used. This can result in a PCB that is not suitable for the intended application, leading to performance issues or even failure. To avoid this mistake, it's important to carefully consider the end-use environment when designing your PCB, including factors such as temperature, moisture, vibration, and other environmental conditions.

Overlooking the manufacturing process

Another common mistake is to design a PCB without considering the manufacturing process. This can result in a PCB that is difficult or impossible to manufacture, leading to delays, increased costs, or even failure. To avoid this mistake, it's important to work closely with your PCB manufacturer to understand their capabilities and limitations, and to design your PCB with these factors in mind.

Not allowing for adequate clearance and spacing

A poorly designed PCB can suffer from electrical interference or even short circuits if it does not have adequate clearance and spacing between components and traces. To avoid this mistake, it's important to follow industry standards and guidelines for clearance and spacing and to carefully consider the electrical properties of your PCB when designing it.

Ignoring signal integrity

Signal integrity is an important consideration in PCB design, as it determines the quality and reliability of the electrical signals on your PCB. Poor signal integrity can result in signal loss, interference, or even failure. To avoid this mistake, it's important to consider signal integrity when designing your PCB, including factors such as trace width, impedance, and return path.

Not verifying the design

Another common mistake is to skip the design verification process, assuming that the PCB will function as intended without testing. This can be a costly mistake, as it can result in errors or defects that are not discovered until the PCB is manufactured. To avoid this mistake, it's important to verify your PCB design using simulation and other tools, to ensure that it meets your specifications and requirements.

Failing to consider thermal management

Thermal management is an important consideration in PCB design, as it determines how well your PCB can dissipate heat. Poor thermal management can result in overheating, which can lead to performance issues or even failure. To avoid this mistake, it's important to consider thermal management when designing your PCB, including factors such as component placement, trace routing, and heat sinking.

Neglecting power integrity

Power integrity is another important consideration in PCB design, as it determines the quality and reliability of the power supply on your PCB. Poor power integrity can result in voltage drop, noise, or even failure. To avoid this mistake, it's important to consider power integrity when designing your PCB, including factors such as power distribution, decoupling, and layout.

Ignoring EMC considerations

Electromagnetic compatibility (EMC) is a critical consideration in PCB design, as it determines how well your PCB can operate in the presence of electromagnetic interference. Poor EMC can result in performance issues or even failure. To avoid this mistake, it's important to consider EMC when designing your PCB, including factors such as grounding, shielding, and filter design.

Comments